Particle Counting in Mining Applications

How Particle Counters can Extend Machine Uptime, Oil Lifetime and Give More Reliability

Mining, whether underground or in an open pit, is heavy, dirty and often wet work, carried out in extreme temperatures, employing robust machinery and hydraulic systems that must perform well in difficult conditions. Specifically, the fluid power systems of these machines are critical and can become contaminated, leading to premature breakdown, efficiency losses, and increased operating and maintenance costs. Fluid power systems in this context indicate hydraulic fluids, lubricating fluids and fuel systems – all of which will be affected by particulate contamination.

Figure 1. Nchanga Copper Mine, Zambia

With equipment costing hundreds of thousands of dollars, and lost production heavily impacting revenues, it is imperative to get maximum uptime from mining machinery. As well as the lost opportunity cost, there are the additional maintenance and repair costs associated with breakdown. Carrying out regular contamination testing for particle counts of the industrial fluids of hydraulically operated equipment can help users to perform predictive maintenance and be proactive before breakdowns occur, increasing uptime and reducing repair costs.

Figure 2. Liebherr R9800 Excavator and dump trucks

Contamination can take many forms and can be introduced to hydraulic and fluid power systems in various ways. Contamination found in systems can include:

- Dirt particles from the surrounding environment

- Dirt introduced during service and/or maintenance

- Spray water ingress

- Poor filtration

- Ferrous and non-ferrous wear particles generated

- Fibres

- Bacteria

- Rubber particles from degrading seals

- Incompatible/non-miscible fluids being mixed

- Contamination from new oil which is unfiltered

- Fuel contamination

Contamination is rarely visible. The human eye can typically see particles of about 40μm and larger. Damage will start to occur when particles 10 times smaller are present in hydraulic and lubricating fluids. Valve clearances can be as small as 1 – 4μm, gear pump clearances can be even smaller – as small as 0.5μm.

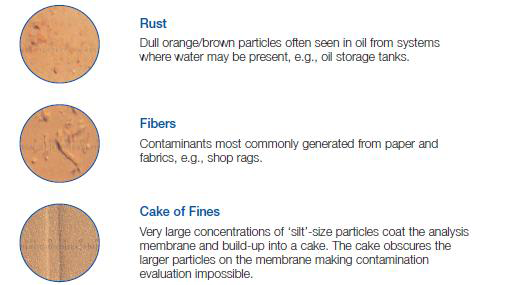

Figure 3. Examples of contamination (Source: Pall Pocket Book)

Most hydraulic and lubricating fluids will absorb water. However, once the saturation point of the oil has been reached, free water will appear in the system, causing:

- Oil breakdown, such as additive precipitation and oil oxidation

- Reduced lubricating film thickness

- Accelerated metal surface fatigue

- Corrosion

By carrying out regular fluid sampling and analysis, users can monitor their particulate levels, and take appropriate action when contamination levels exceed pre-determined target cleanliness levels (TCL). This could be, for example, carrying out an in-depth analysis of the fluid to determine what is causing the increased particulate levels, and then taking the appropriate action to return them to below the target cleanliness levels by running a kidney loop filter system, replacing filter elements, replacing system components or replacing/ servicing the oil.

Figure 4. HIAC PODS+ Portable Particle Counter

Particle Counters offer many advantages over ‘traditional’ methods of contamination analysis such as membrane analysis. Particle Counters are calibrated with traceable calibration materials in accordance with ISO 11171, and so offer quick, accurate results, excellent repeatability, and the ability to trend data over time. Fluids can be analysed directly on-machine using the HIAC PODS+ Portable Particle Counter, and results are available almost immediately, typically within 30-60 seconds. Alternatively, bottle samples can be collected and analysed in the central laboratory using a laboratory analyser such as the HIAC 8011+, with results again in around 30-60 seconds. As particle counters are automatic, the human error factor is removed, ensuring that data is accurate and repeatable.

Figure 5. HIAC 8011+ Laboratory Particle Counter

Particle Counters work by measuring the number of particles in the fluid at various sizes, and then automatically reported as defined by National and International Standards such as ISO 4406 and SAE AS 4059.

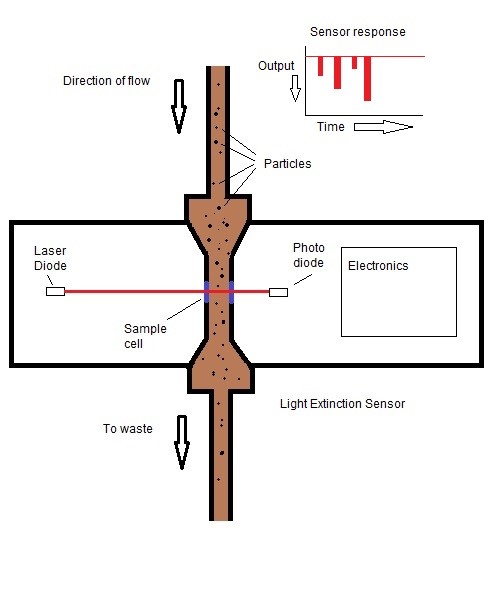

Particle Counters use the ISO approved light extinction method of particle detection. The technology used is simple and robust, which makes this detection technique appropriate for in-field use.

The sensor includes a sample cell which allows the sample fluid to pass through. The sample cell includes a sapphire window, which allows a laser beam to shine through it and the fluid onto a photo detector. Fluid is passed through the sensor at a predetermined, accurately controlled, and calibrated flow rate. When the fluid is very clean, nearly the full power of the laser reaches the photo diode (detector), as nothing blocks the laser, and the signal output from the photo detector remains stable. However, when particles are present, they intermittently block some of the light from reaching the photo detector. The amount of light blocked, is directly proportional to the size of the particle. The larger the particle, the more light is blocked, and subsequently the larger the amplitude of the pulse output from the photo detector.

Figure 6. Theory of operation - Light Extinction Sensor

By incorporating particle counters into maintenance routines, users will gain control over their contamination levels, allowing them to run efficiently and productively, reduce breakdowns, and reduce maintenance and fluid costs.

Beckman Coulter offer three products –

- The HIAC 8011+ Laboratory Particle Counter, with automatic fluid degassing, automatic flow regulation, and multiple calibration capabilities for petroleum based to aqueous based fluids, in addition to fuels.

- The HIAC PODS+, portable Particle Counter, which can analyse both online and by bottle sample, is a true multi-fluid analyser, with the option for moisture measurement in petroleum-based fluids.

- The HIAC ROC remote online counter, designed to be fitted into a dynamic hydraulic system and to report the system cleanliness level 24 hours per day, 7 days a week.

For more information, please contact your local office or representative. You can find more details at beckman.com/hiac

Acknowledgements:

The author thanks the following for their help in putting this document together:

- Pall Corporation for allowing the use of images from the Pall Pocket Book

- Liebherr Group for permission to use their images of excavators.

- Bill Bars, Beckman Coulter, for his invaluable input.

Author: Matt Harle, Sr. Field Marketing Manager